Consulting Group

We Provide

Lean Sigma Training & Certification

Page 3 of 3

Go To Market Strategy:

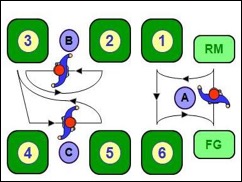

We provide a fresh approach from Toyota Production System for a flawless launch of new products from inception stage to customer delivery acceptance.

- Market survey using Conjoint Analysis & Focus Groups

- Use of 2P & 3P (Product Preparation Process)

- QFD (Quality Functional Deployment)

- NPD (Launch Tollgate Process)

- Capacity Modeling

- SWOT analysis

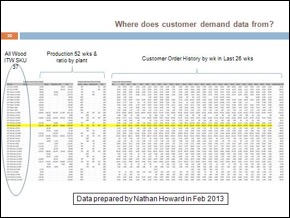

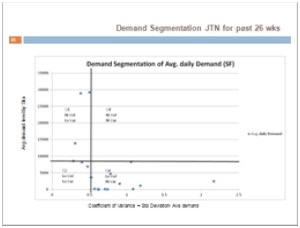

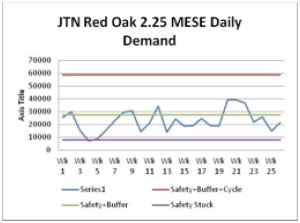

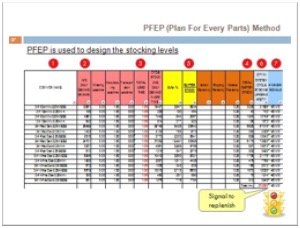

- Demand Segmentation (SKU Resolution)

- DFSS (Design for Six Sigma)

- DFM (Design for Manufacturing & Assembly)

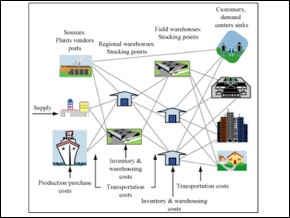

- Material and Distribution Supply Chain

- Global Project Management Deployment

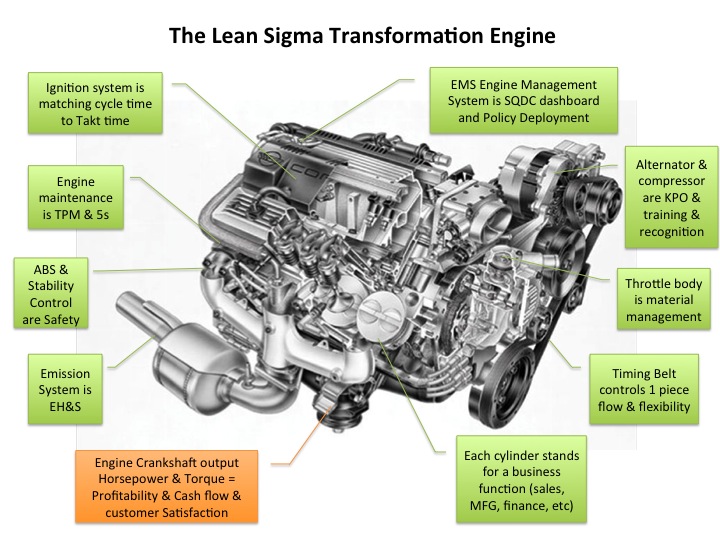

Lean & Six Sigma Training & Certification:

Our instructors are formally trained CERTIFIED Black Belts and Master Black Belts with extensive Fortune 100 company experience.

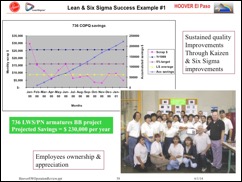

Our philosophy is helping our students to use the new knowledge immediately and apply it to solving his/ her business problems. We help our students continuously to audit their analysis and improvement actions. Devise simple but effective metrics to monitor leading performance indicators.

Our program is strongly tied to measureable financial result in profitability and cost of capital. Extensive use of balance sheet (P&L statement) working directly with company controllers and CFO's)

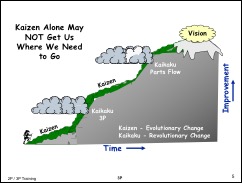

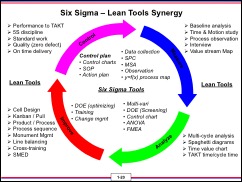

Lean Training & Development:

- Benchmark Toyota Production System and customize to our clients environment and requirements.

- Lean Enterprise approach in Transactional (business process) and Manufacturing Process.

- Build on the success of Progressive Managing for Daily Improvement (MDI)

- Multiple training levels depending on client's organization structure, budget, and resources (from KPO leads, Champions, Sponsors, Lean Masters and Deployment Directors)

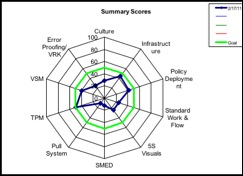

- Provide formal Lean assessment to document baseline and annual progress

- Construct actionable internet base Lean Portal for tracking progress

- Develop Enterprise level Policy Deployment culture and methodology

- Strong and dedicated focus on personal and team development

- Specialized in Total Quality, System Reliability, EH&S, and Human Resources

- Use VSM & VSA (Value Stream tools) to document current & future states, as well as surgically deploy Six Sigma projects.

Six Sigma Training & Development:

- Formal online or onsite Green Belt and Black Belt training with a full currimulum of DMAIC modules

- Reinforce Standardize, Stablize, and Improve.

- Thorough use of statistical tools and software by Minitab (Certified Instructor)

- Each student is assigned a Real World Business Problem at work with a Champion. A critical requirement for course completion.

- Each student is assigned a coach for project completion

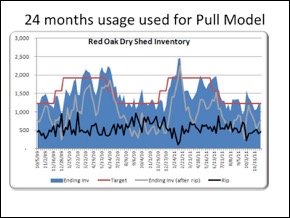

- Extensive use of business historical data on both transactional and manufacturing processes.

- Focus equally on the process (How to get there) as much as the result.

- Extensive use of Regression and DOE to accurately determine reliability and predictability on future results and sustainability.

- Use to complement Lean concepts to reduce variability and predictability.

Certificatons:

- We work closely with our clients to deploy a disciplined certification programs for recognition, succession planning and motivation.

- It is not an entitlement, but must be earned through hard work and result.

- Lean levels - Kaizen leader, KPO leader, Lean Master, SME's, Lean Champion, Lean Sponsor, Director of Lean Deployment

- Six Sigma Levels - Green Belt, Black Belt, Master Black Belt, Champion

- Work closely with Human Resources and Senior Management to link certification with Succession Planning & Career Development.

- Issue formal diploma and certificate.

Kaizen Promotion Office (KPO):

- Use to re-deploy displaced team members from Kaizen events to promote future business growth

- Train SME's and basic Kaizen methodologies

- Deploy for 5s and MDI activities as well as HR onboarding assistance.

- Provide a labor pool for turnover or absenteeism.

- Develop a culture of "No one loose their job because of Kaizen"

- Help in developing DOJO training centers

Supply Chain:

We provide real world support to the commercial and military aerospace service business.

Types of Transactional Processes:

- Contract negotation

- Document Control & Compliance

- Project Planning & Scheduling

- Estimations

- Engineering (Design & Process Control)

- Quality System & Audits

- Production Control

- Production Planning & Control

- Manufacturing

- Assembly & Fabrication

Types of Manufacturing Processes (Aluminum & Titanium):

- Machine Setup

- Material Flow

- CNC & Laser Machining

- Computerized Measurements

- Heat Treating & Forming

- Polishing & Inspection

- Final Assembly & Fabrication

AeroSpace Products