Consulting Group

Our Smart Lean Sigma Training Product

Our Smart Lean Sigma Training & Development Products

Categories of training & development kits

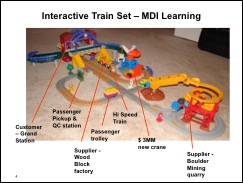

GeoTrax (R) Train Set - an introduction to a Lean Culture (the elimination of wastes) :

This is a entertaining and non threatening training for everyone in your organization. It is an abnormality paradym buster with a long lasting cultural impact.

The business delivers products through a complex and costly value stream. It is losing money because the cycle time is much higher than takt (customer demand). The students must measure and analyze the current wastes. Then reduce the non value added work through significant waste eliminations. Selecting a faster train is not the solution. The final test is to challenge the student to teach a new employee how to run the improved business. They will learn the secret and the importance of a well executed standard work. During this game, extra points are awarded for 5s audits and safety improvements. The team also learns about how a profit and loss balance sheet is developed.

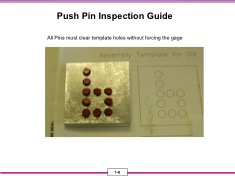

Experience 100% inspection is only 80% effective.

Safety is #1

Learn to apply Poke Yoke

Customer's demand is unpredictable

Experience the painful cost of quality rejections

Apply visual Kanban concept & replenishment

Learn Line Balancing & bottleneck

Learn SMED & Quick Changeover

Learn profitability and cash flow to value a company

Pricing & Availability:

Deluxe kit (4 color pins, cork board, QC jig) - USD $250 ( 2 weeks delivery US only)

Group sizes & duration:

Best for 8 to 12 people class sizes (can divide into 4 people group competitions)

Generally last 30 minutes for each heat. Best to run competition daily during the week long Lean/ 6 sigma class.

Suitable for all management levels from shop floor to C-level management.

Final day competition with prizes.

Training & development kits

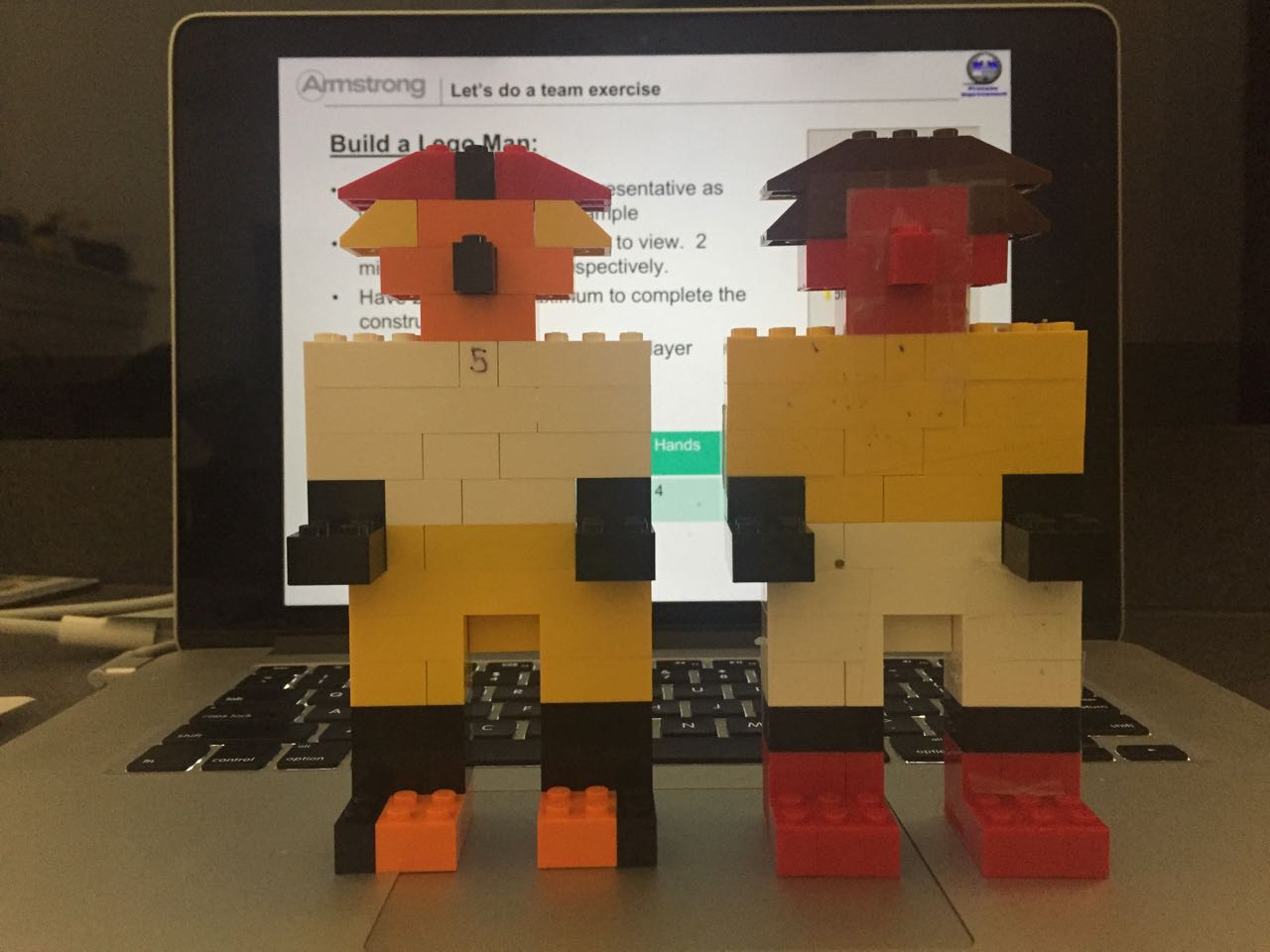

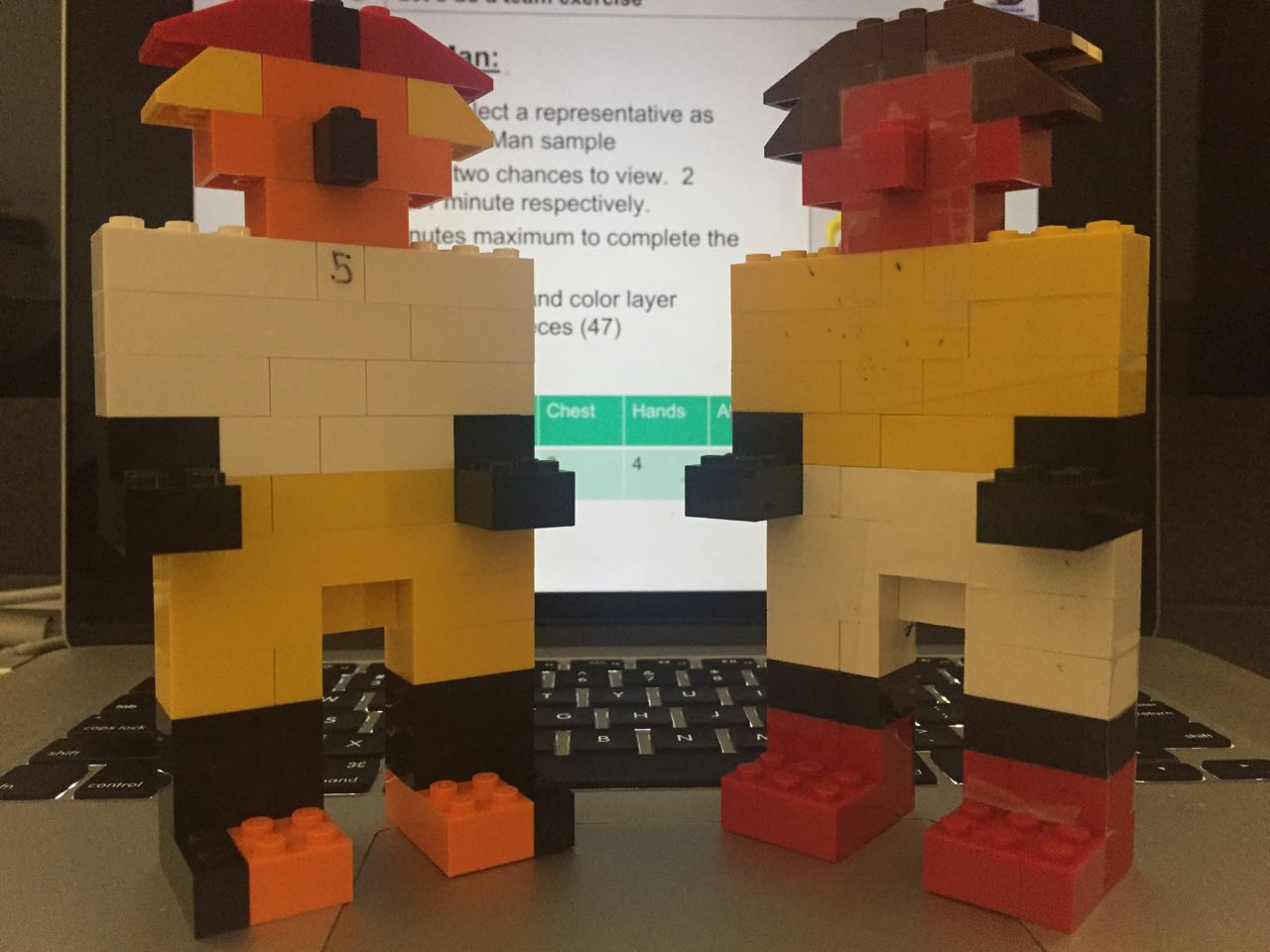

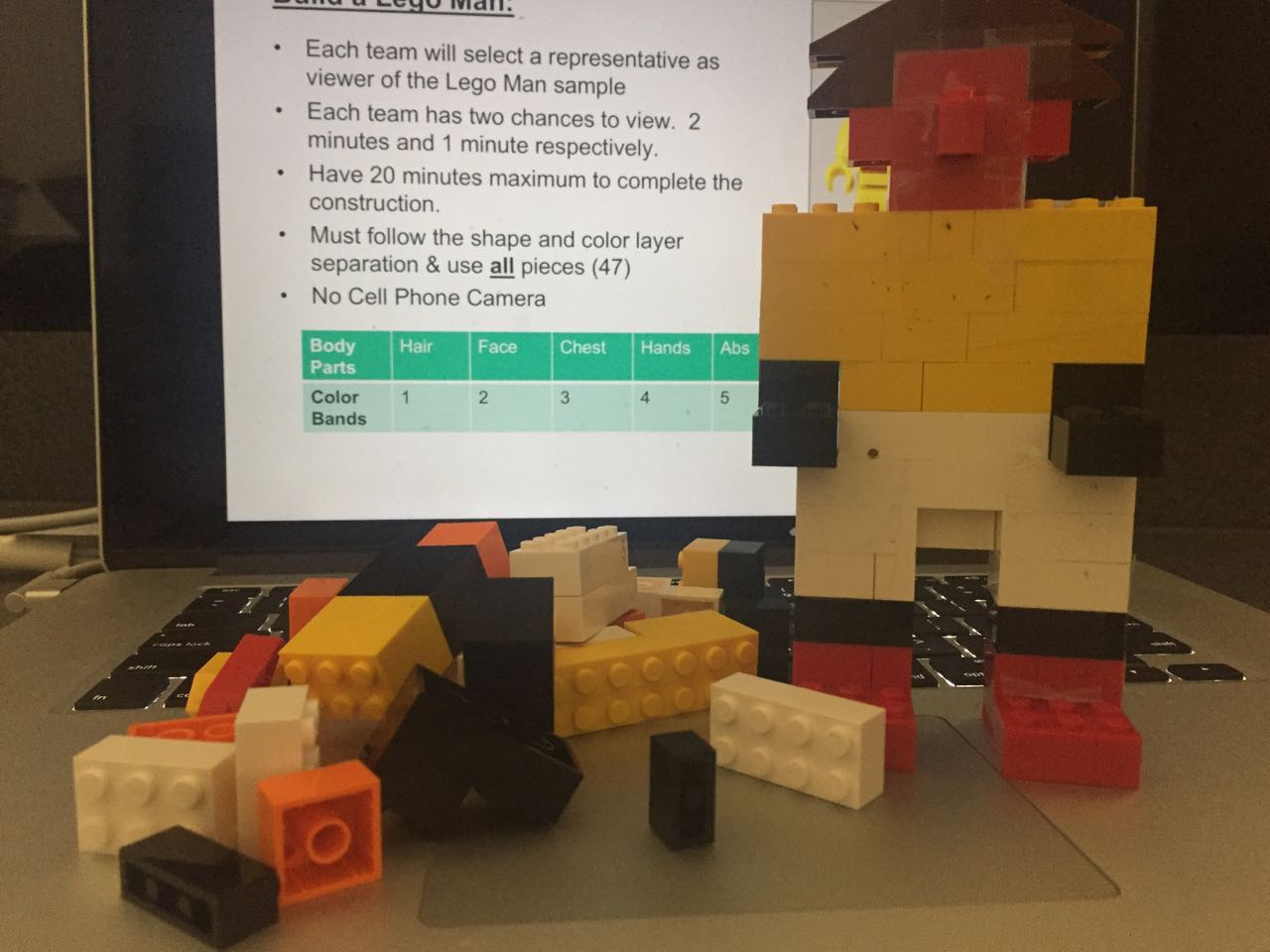

02 LegoMan - Teaching project management & team engagement :

A competitive game which involves leadership skills, communication, time management, conflict & stress controls. The team will walk away with a much greater respect of a broader view of a company in the eyes of the customers.

Each group of 4 people is requred to reconstruct the LegoMan to match the standard sample. They are required to use all 47 given loose Lego blocks and complete in under 20 minutes. The only instruction is an observation time of 3 minutes to view and record the construction build (without taking a picture with mobile phone). It is a scramble of chaos and plenty of yellings and spyings. The instructor can observe the behavior of each groups during the competition. Most teams fail to match the sample LegoMan figure and often come up with hilarious shapes and left over pieces. There is usually 1 winning team in the group that meet the challenge. In the debrief, the instructor can comment on the importance of team work that often causes disruptions and infighting with various business functions within a dysfunctional company.

Learning Features:

47 Lego pieces, 40,320 combinations, only 1 solution.

The importance of planning even under extreme stressful situation

Sharing of responsibilities (no blame attitude)

The difference of a boss and a leader

Sharing of best practice vs a lone ranger

Theory of Constraints

Logical thinking

Communication (visual, verbal, & kinestatic)

Empathy & sharing of success

Pricing & Availability:

Basic kit (2 LegoMan figures) - USD $ 50 (3 days delivery)

Deluxe kit (5 LegoMan figures) - USD $100 ( 1 week delivery)

Additional LegoMan - USD $30 each

Group sizes & duration:

Best for 4 people team with 3 to 5 teams together.

Generally last from 30 minutes to an hour.

Suitable for all management levels from shop floor to C-level management.

Designed for project management & team development

Training & development kits

03 Lego Batch & Flow Simulation Kit - a true eye opener for non believers :

Lego Town Development Project is a hands-on demonstration to experience the huge gain in productivity by reducing batch sizes. It happens in both transactional and manufacturing processes

This game is broken down into 4 different competition heats. The challenge is to deliver 12 sets of assembled widgets to the customer in the shortest time and with the least amount of finished inventory (Raw, WIP, and FG). The first heat is a base line run with a production batch of 6 widgets. In each heat (run), the time of the first delivery to the customer is recorded as well as the total production time and the finished inventory. The factory will continue to produce ( show overproduction) until the customer recieves the first delivery (batch) complete. The team is instructed to appy 5s to organize parts. The subsequent runs are in batches of 3, 2, and finally a 1 piece flow. The students can see a very significant (exponential) reduction of production cycle time when the batch sizes are gradually reduced. Also the customer receives his products much sooner leading to faster cash flow and customer satisfaction. The total inventory is also reduced due to the elimination of overproduction and total unused inventory. This scenario is foreign to the normal way Industrial Engineers calculate time value using a linear production method. It completely changes the misconcept that running large batches is more effective because there is no need of frequent changeovers. This exercise is especially an eye opener to the business (transactional) employees, because more business processes are structured to work in large batch sizes (by days, or by weeks). This game also touches briefly on a balance work flow and cellular manufacturing.

Learning Features:

Demonstrate the power of simple 5s organization

It Stresses the evil of time wasted by waiting especially in office process

Demonstrate interaction of Takt time and Cycle time by time observations

Show the impacts of imbalance work flow caused by design...not people

Show incremental gains in productivity by gradual batch size reductions

Show batch sizes can significantly affect time to market

Introduction to cellular manufacturing and Kanban replenishment

Demonstrate the power of flexible and agile manufacturing

Show how batch sizes can affect cash flow.

Pricing & Availability:

Basic kit (12 Widgets with carrying case) - USD $ 200 (1 week delivery)

Deluxe kit (24 Widgers with carrying case ) - USD $300 ( 2 week delivery)

Additional warehouse, trucks & forklifts - call for quote.

Group sizes & duration:

Best for 5 people team with 3 to 5 teams together.

Generally last from 60 minutes to 2 hours.

Suitable for all management levels from shop floor to C-level management.

Great for finance, mfg, and supply chain

Training & development kits

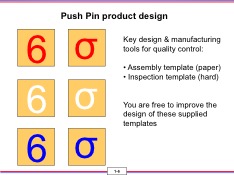

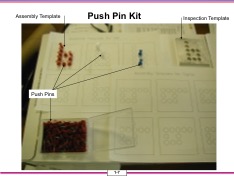

04 Push Pin Lean Factory Simulation Kit - learning to see SQDC (safety, quality, delivery & cost) in action.

Students can apply the Lean and 6 Sigma tools to create a true lean enterprise in order to meet customer demand. They have to meet Takt and Quality requirements. Supply chain challenges can affect the bottomline and also affect parts shortages.

Transforming a traditional business into a Lean Enterprise requires stakeholders that understand and embrace the SQDC discipline and execution. This simulation game is used during a week long Lean or Six Sigma training class. At the end of each day, the instructor would ask the students (in groups) to apply the daily learning and continue to improve their respective factory design and manufacturing methodology. The students find out quickly that without quality, speed is meaningless. The class must develop a flexible manufacturing structure to win the team competition on the final day. The customer can change his order quantity and mix styles anytime. This game really brings the Lean and Six Sigma tools seamlessly together. The competition is intense and challenging till the very end.

Learning Features:

Quality & Quantity are inseparable.

Poke Yoke is more effective than 100% inspection

Simplcity is better than elegance

Make it a visual factory

Takt time vs Cycle time

Test and Validate constantly

Always consult with the customer (CTQ)

Flawless exectuion comes with practice

Pricing & Availability:

Deluxe kit (for 4 teams) - USD $ 250 (2 week delivery)

Group sizes & duration:

Best for 5 people team with 3 to 5 teams together.

Generally last from 30 minutes to an hour for each run at each of each day.

Best for a week long Lean Sigma training class

Suitable for all management levels from shop floor to C-level

Training & development kits

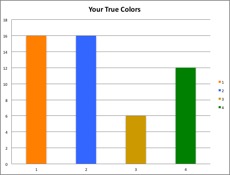

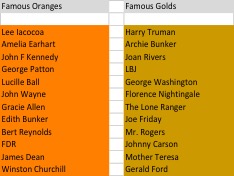

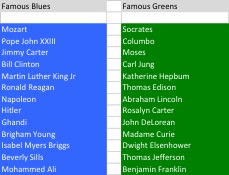

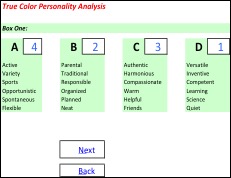

05 True Colors Self Assessment Kit - learning to interact successfully with others.

A user friendly software to understand your inner self of Strengths, Joys, Values, and Stressors. Also with the person you are dealing with.

This can be a powerful and impactful exercise for soft skill development in any organization. The test can be administered in private in less than 20 minutes on any computer. The graphical color display provides the user to understand his/ her true self in 4 different colors (Orange, Gold, Blue, and Green). The colors stand for our respective strengths and stressors. Although it is very difficult to alter ones character, it allows us to control our behaviors. By being more aware of ourselves and the environment, we can increase our success rate in negotiations, defuse hostile encounters, and gain alliances in our business practices. It is especially useful working in today's diversed work force.

Learning Features:

- Low cost with Unlimited use.

- Easy to use with instant result

- Offer a memorable experience for life

- Self contained instructions and reference material

Pricing & Availability:

Excel Macro Softare (with instruction) - USD $ 45.00 (1 day delivery)

Group sizes & duration:

Can be used individually or in a class environment.

Generally takes 10 to 20 minutes to complete the test.

Proven success around the world.