IDM certified instructors have extensiive experience in real world practical applications. We customize the training curriculum to fit your needs, resource, and budget. We can enhance your online training with hands on project coaching. Our training is focused in these vital business & personal growth areas. Our goal is to grow your internal bench strength of problem solving skill for your team members and future leaders.

TWI (Training Withini Industry) program has a direct impact in development and use of Kaizen and Standard Work in Toyota.

Six Sigma & Design for Six Sigma (DFSS)

- DMAIC (GreenBelt, BlackBelt, and Master Black Belt) training & mentoring

- DFSS (NPD, QFD, Statistical Tolerancing, FMEA, Finite Elements)

- Statistical process control (Minitab training)

- Business go to market Regression Analysis and prediction.

- Testing & Certification of BB, GB, and MBB.

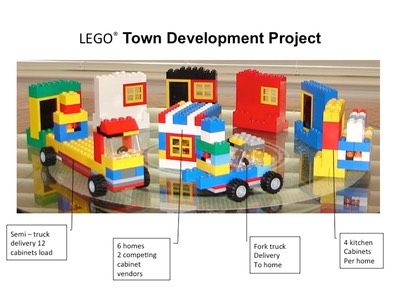

Lean Process Improvement

- Toyota Production System & Applications (Waste Elimination)

- Kaizen Methodology

- Theroy of Constraints

- Progressive MDI

- Demand flow technology & Capacity Planning

- Demand Segmentation & Go To Market Strategy

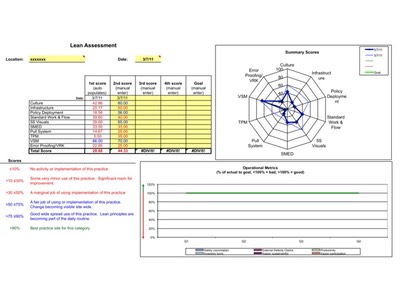

- X-Matrix & Goal Deployment (or Policy Deployment)

- VSM/VSA & Hoshin Calendar

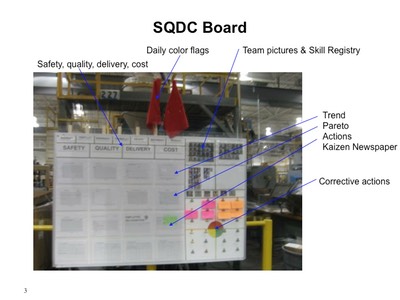

- Visual Work Place (SQDC, Hr x Hr, War Room, Gemba Walk)

- Logistics & Supply Chain (Scheduling, Planning & Inventory Buffering)

- 2P & 3P (product, process planning)

- Leader Standard Work

Soft skills and leadership development

- Change & Risk Management (cultural & tactical)

- Team Development (True color personal traits, dysfunctional traits)

- Everyday Creativity

- Negotiation skill (customer - supplier servant leadership)

- Project Management (Work Breakdown Structure, Critical Path, Gantt, Resource)

- Communication skill (presentation, speaking, listening, writing)

- Time Management (Leader Standard Work, Value & non Value added work)