1. Plastics Injrection Molding Material Handling and Defect Reduction - Using 2P methodology to reduce setup and handling damages. Solved bottleneck in a key component’s value stream.

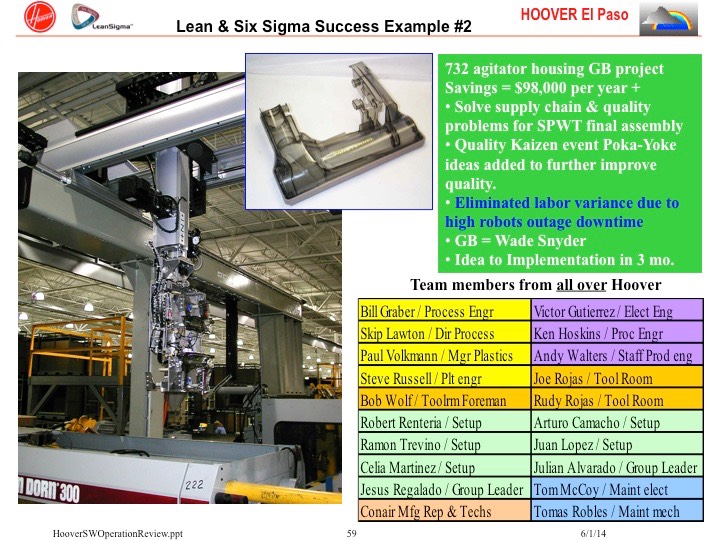

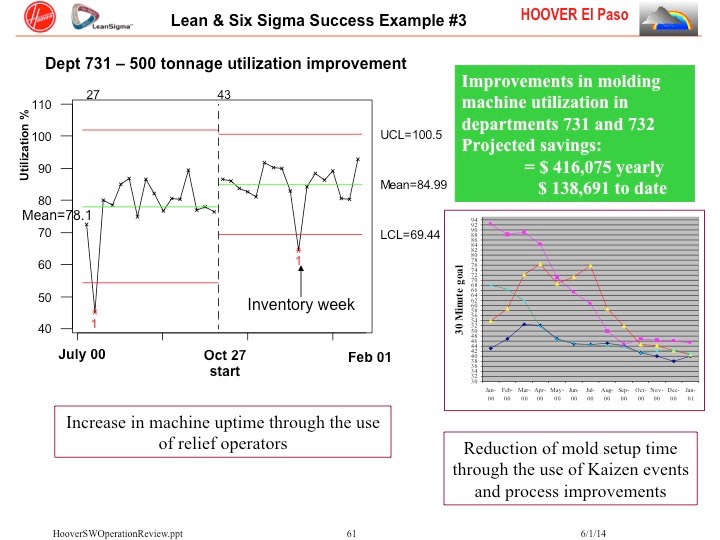

2. Machine OEE Improvement - Use of SMED in molding press die changeover time and also eliminate setup defects. Improve safety with standard work and job rotation.

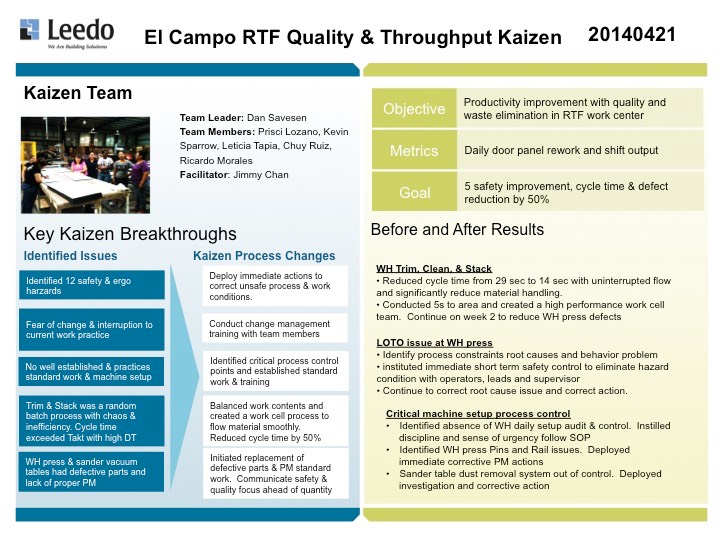

3. Door Lamination Quality & Throughput Improvement - Waste elimination, TPM, safety improvement, standard work and cultural changes to eliminate process constraint, and overtime work.

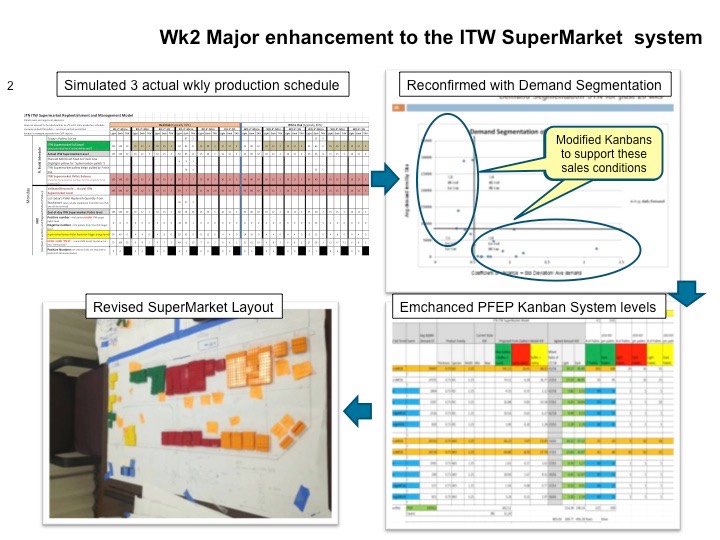

4. Manufacdturing Flow Improvement - Design and Implement a comprehensive Kanban Supermarket Replenishment System.